Key Label Printing Tech

The are many technologies for printing the key label on the keycaps.

Pad Printing

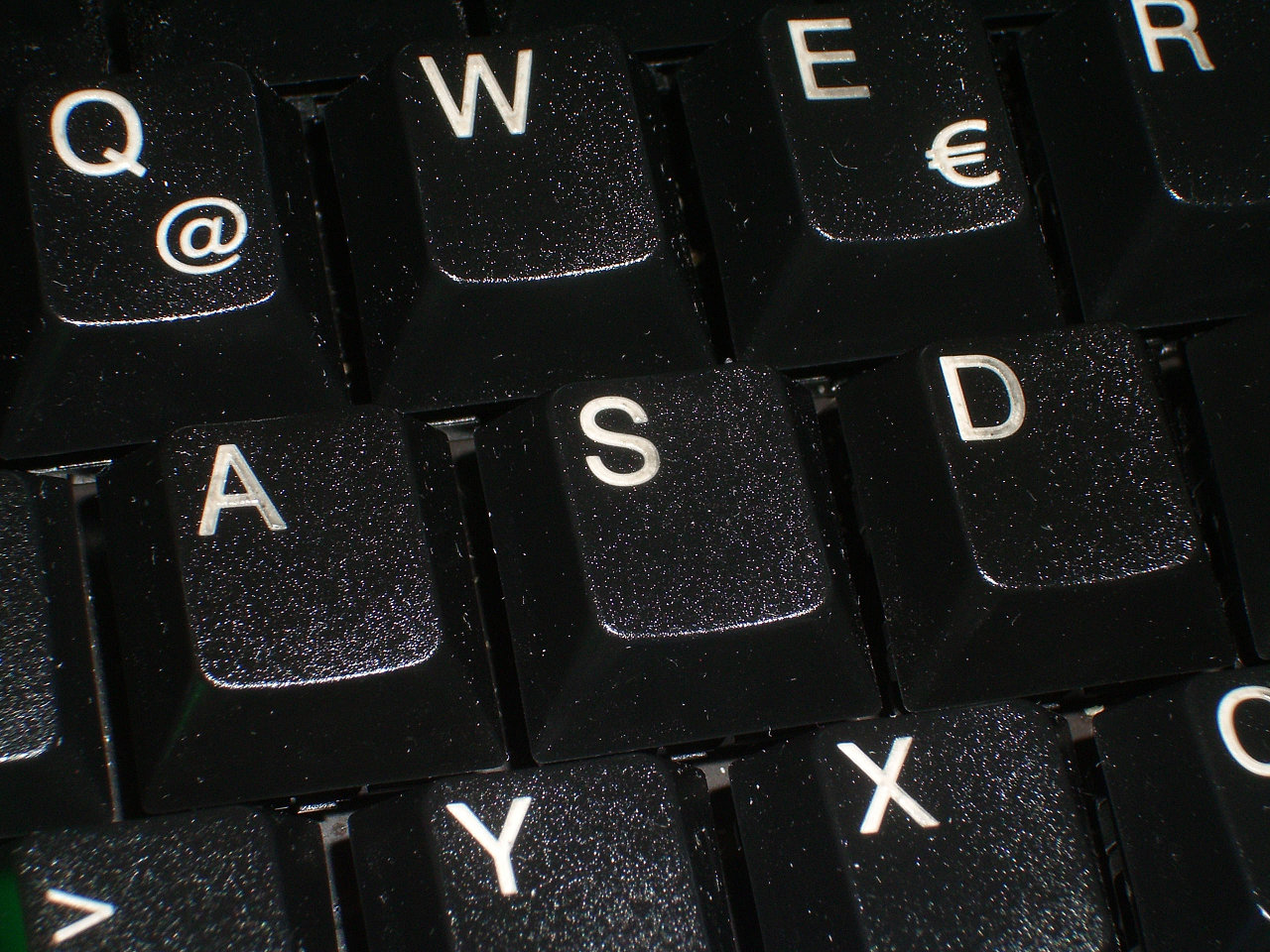

Pad Printing is the most commonly used.

Pad printed key wears off fast. It can wear off after a year.

You can easily tell pad printed labels. It looks like a transparent sticker.

Almost all Microsoft and Logitech keyboards are pad printed.

Laser Marking

Laser Marked key labels don't wear off, but they have limitations in color, contrast, sharpness. And has difficulty printing filled areas such as Window logo or Apple logo.

There are several techniques using laser to print key labels. They include:

• Laser marking. many subtle techniques. e.g. UV laser ionize the material and change the color.

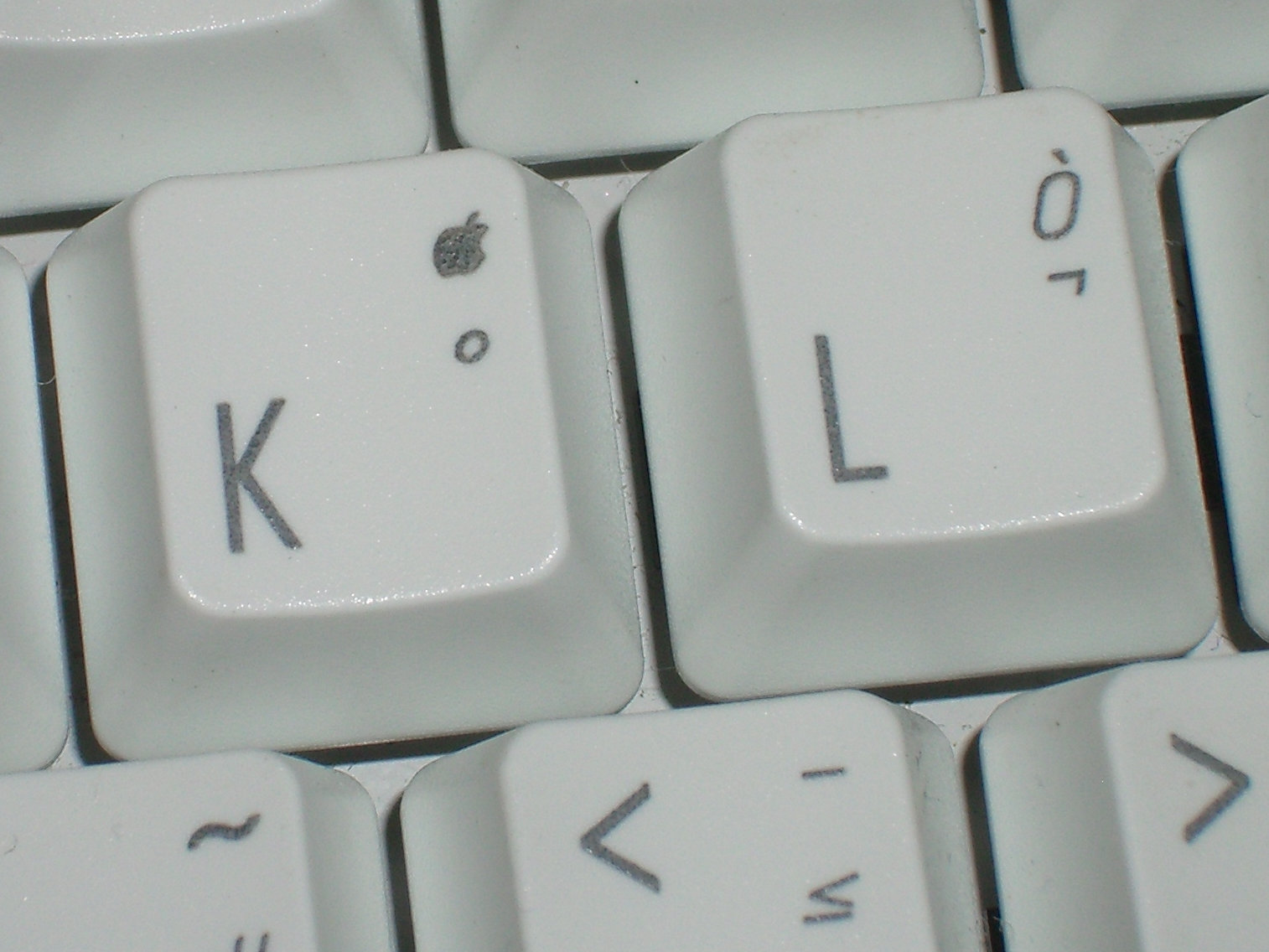

• Laser charring. Using laser to burn the plastic. Basically, burn white plastic into grey labels. This can only be done for white keycaps. And, the label is not high-contrast.

• Laser engraving. Using laser to burn a groove. The groove can be filled with paint. The disadvantage is the infill are easily stained.

〔see Matias Mini Tactile Pro Keyboard〕

- https://youtu.be/LZneieuvmw8

- French/Swedish laptop keyboard laser engraving machine Russian keyboards laser marking machine

- Emily - Supernova Laser

- Published on Jan 25, 2016

Dye sublimation

Dye sublimation is a process where heat is used to impregnate a material with a dye. This is different to printing in that printing forms a layer of paint on top of the plastic, whereas dye sublimation causes the dye to sink into the plastic. Dye sublimation was a popular method for keycap printing in the 1980s and 1990s. Because the dye permanently stains the plastic, it cannot be worn off like paint, and unlike laser printing, it can be used to easily print a mixture of different colours.

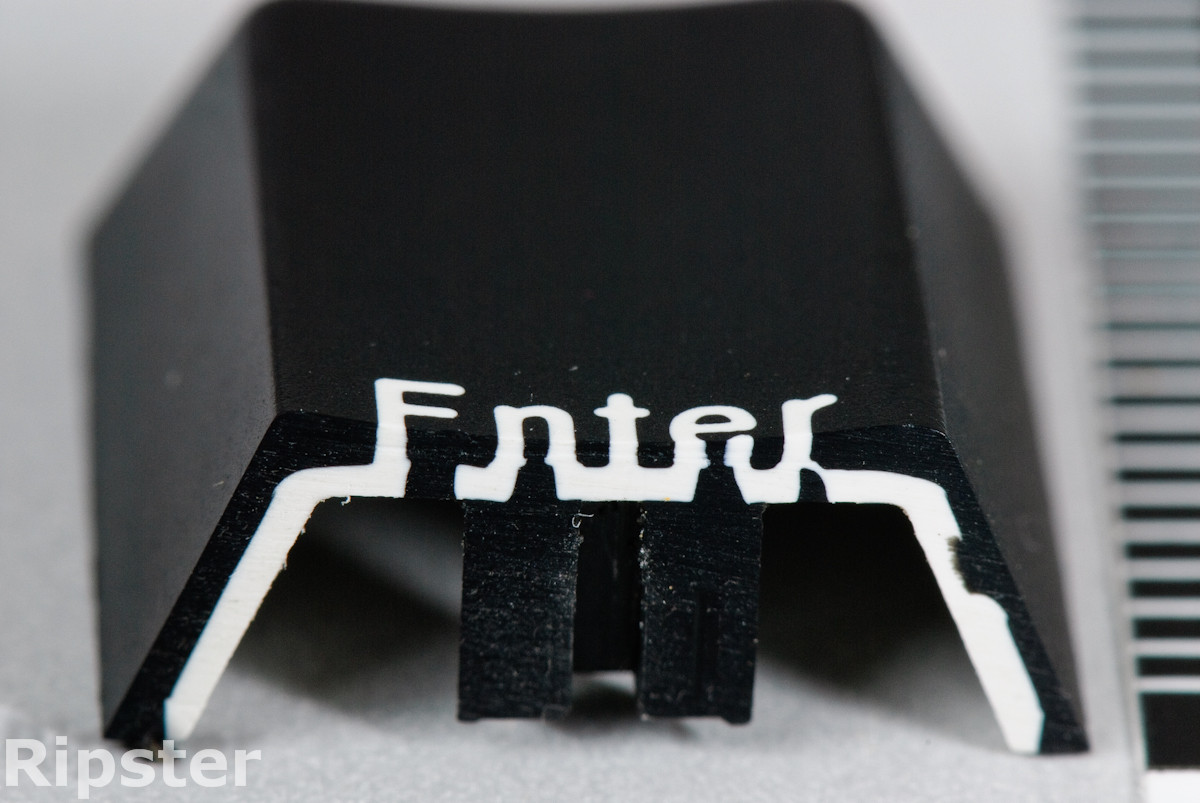

Double-shot injection molding

This is considered best, and also most expensive process.

Double shot injection molded keycaps are often considered the best type of keycap. Rather than print the legend onto the keycap, the legend is molded from one colour of plastic, and then the remainder of the keycap is molded around it in another colour of plastic. This process has the advantage of producing markings that cannot be worn off, as they are physically part of the keycap. The process also provides high contrast as the legend is not affected by the colour of the surface of the keycap.

Print in Front-Side of Keys

One excellent method in key labeling is to print the label in front of key.

The advantage is that it won't wear out, as fingers don't touch it.

You can buy keycaps with front-printed labels.

Reference

- Ripster Keyboard Science: Doubleshot Keys

- By Ripster.

- https://imgur.com/a/OhRd4#NV57Oxa

https://deskthority.net/wiki/Keycap_printing

Many photos on this page are by Daniel beardsmore. https://deskthority.net/wiki/User:Daniel_beardsmore. Public domain.

Apple (Standard) Keyboard (M0116), 1987

Apple (Standard) Keyboard (M0116), 1987 Keycaps: ABS, PBT

Keycaps: ABS, PBT Key Label Tech

Key Label Tech Cute Keycaps

Cute Keycaps